✨AI 추천 연관 상품

AI가 분석한 이 상품과 연관된 추천 상품들을 확인해보세요

연관 상품을 찾고 있습니다...

Modular Isolators for quick delivery.

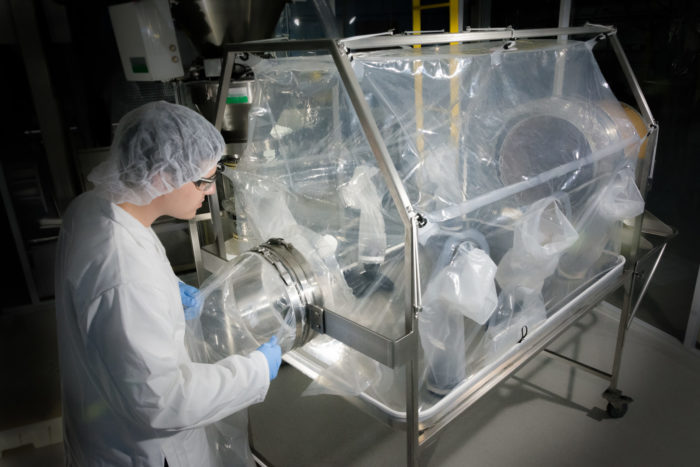

ILC Dover has been a pioneer in developing flexible isolators, (aka glove bags), for the pharmaceutical industry. After 20 years of designing and building custom isolators for powder containment, our engineers have compiled and standardized isolator specifications, dimensions, configurations, and components that meet the vast majority of our customers’ needs.All materials meet FDA standards and the design accommodates cGMP as well as operator ergonomics. These standardized, modular designs allow quick delivery of isolators to handle many contained pharmaceutical powder handling processes.

Features and Benefits

High containment flexible isolators for processing HP API powders

Great visual clarity of ArmorFlex® films

3rd party validated nanogram containment levels using SMEPAC guidelines

Ergonomics and range of motion are much better than with rigid isolators

Economical

Design makes use of existing ILC Dover containment accessories such as CrimpLoc® crimps, bag/out sleeves, and O-ring interface canisters

Compatible with DoverPac® powder transfer systems

The passive isolator can be upgraded to a fully automatic negative pressure isolator using the ILC Dover our JetVent system

Fast turnaround & installation

Applications

Weigh and Dispense operations

In-Process isolator systems

Drum transfer processes

Enclosing small, table top powder handling equipment such as mills, sieves, & blenders

Technical Specifications

Frames constructed of 304 stainless steel

All surfaces have a 2B finish

Product contact components constructed of 316 stainless steel

Flexible isolator made from ArmorFlex® 113 and ArmorFlex® 114 films

Drum rings and canisters use ILC Dover patented multiple O-ring connectors

Accessories

배송/결제/교환/반품 안내

배송 정보

| 기본 배송비 |

| 교환/반품 배송비 |

|

|---|---|---|---|

| 착불 배송비 |

| ||

| 교환/반품 배송비 |

| ||

결제 및 환불 안내

| 결제수단 |

|

|---|---|

| 취소 |

|

| 반품 |

|

| 환급 |

|

교환 및 반품 접수

| 교환 및 반품 접수 기한 |

|

|---|---|

| 교환 및 반품 접수가 가능한 경우 |

|

| 교환 및 반품 접수가 불가능한 경우 |

|

교환 및 반품 신청

| 교환 절차 |

|

|---|---|

| 반품 절차 |

|