✨AI 추천 연관 상품

AI가 분석한 이 상품과 연관된 추천 상품들을 확인해보세요

연관 상품을 찾고 있습니다...

Photobioreactors

Photobioreactors are guiding technology for a sustainable future. bbi has integrated the experience of Prof. Pulz in photobioreactor engineering, design and construction into its own life science portfolio after 30 years of know-how production at IGV. Novel automation systems and optimized operational parameters are implemented in bbi’s upgraded photobioreactor series, while we still rely on horizontal glass tubes as main photobioreactor material.

Photobioreactor Engineering and Design

A photobioreactor supplies light and CO2 to microalgae and other plant cells. The algae grow to a dense green, red or brown liquid when additonally supplied with nutrients. The harvest of microalgae biomass is done with centrifuges or sieves after the algae culture has reached maximal cell count or dry biomass content. Smaller installations are operated batch-wise, while scaled photobioreactors are operated in fed-batch-mode.

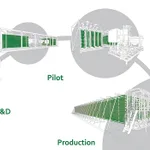

bbi supplies photobioreactors from lab- up to production scale. The successful scaling of our design principles is founded on the application of high-value glass tubes, which do in contrast to other plastic plate or bag systems allow modular and centralized photobioreactor construction layouts. High-end in-situ steam-sterilizable research phototobioreactors for high-level R&D are possible as well as production photobioreactors for greenhouse or outdoor installation.

The glass tube application provides advantages as follows:

- Optimal illumination of thin algae suspension layers

- 100% flat surfaces prevent immobilization and biofouling

- 100% flat surfaces for minimized pump energy input

- Both best transmission rates and light-fastness

- Guaranteed glass tube shelf life of at least 10 years

- Reduced investment in comparison to plastic materials

We supply system solutions. We combined proven photobioreactor components with our xCUBIO Bioreactor Toolbox. We contributed automation systems and other technological parts or even did the whole project execution for more than 100 of IGV’s photobioreactors. This know-how has been used to expand our product portfolio after the successful agreement with IGV in March 2015. We are now able to supply novel photobioreactors, which are equipped with a handful of optmizations. Our customers are R&D-departments of both companies and universities but we do also support projects for the erection of scaled algae production installations with technology from our own life-science workshop.

Please take a closer look at our high-value photobioreactor designs on the following tabs:

xCUBIO phar: High-End Microalgae Research

- Overall volume app. 5 Litres

- Glass tube app. 9 m long with 20 mm diameter

- LED-illumination with up to four separately controlled wavelengths and multiple cycle regimes

- Internal system vessel for CO2-feed, oxygen removal, tempering, sensor installation and level control

- Autoclavable circular system pump with magnet coupling for high flow rates, successfully tested with many algae strains

- System devices with contact to algae autoclavable in lab-autoclave after finished mounting and media filling

xCUBIO in-situ phar: in-situ Sterilizable Photobioreactors

- Fully automatic sterilization with steam

- Operational volume from 25 up to 250 Litres

- All media contact devices are stainless steel

- Accredited for GMO-cultivation

- Possibility for qualification and validation

- GMP- and FDA-compliant design

- Cultivation even of the most sensitive microalgae species

MEDUSA – in-situ Sterilizable Air Lift Photobioreactor

- Bubble column by airlift principle

- Standardized volumes 25, 50 and 100 Litres

- For microalgae, mosses and plant cells with high sensitivity towards shearing stress

- For extreme purity requirements

- Fully in-situ-sterilizable with steam, steam generator available as an option

- All media contact devices are high-value borosilicate glass

- Controlled illumination with fluorescent tubes

Photobioreactors for Microalgae Cultivation in the Lab

- Operational volume from 25 up to 250 Litres

- High-value xCUBIO process automation with touch-screen and remote access

- Artificial illumination with controlled sequences or natural light

- Compact skid installation on mobile steel frame

- Pretested and ready for operation immediately

- Interfaces: electrical supply, CO2, fresh water, waste water

Your Successful Start into Microalgae Production

- Operational volume from 1000 up to app. 8000 Litres

- Scaled process technology in modular, mobile construction and flexible design

- Simple and robust construction with high operational availability

- Artificial illumination available as an option

- Integrated supply of harvest system with separator available as an option

- Inoculum production for scaled algae production systems

- Production of test biomass for product development and marketing

- Interfaces: suitable installation area, electrical supply, CO2, fresh water, waste water

Scaled Microalgae Production Installations

- Operational volume of singular photobioreactor modules up to app. 100’000 Litres

- Industrial up- and downstream technology

- Algae cultivation in greenhouses or outdoors

- Glass tubes with more than 10 years guaranteed shelf life

- Project specific CAD-engineering in 2D and 3D

- Installation with competent technical advise

- Commissioning service and remote maintenance

- Reliable and predictable production

- Interfaces: suitable installation area or building, electrical supply, CO2, fresh water, waste water

배송/결제/교환/반품 안내

배송 정보

| 기본 배송비 |

| 교환/반품 배송비 |

|

|---|---|---|---|

| 착불 배송비 |

| ||

| 교환/반품 배송비 |

| ||

결제 및 환불 안내

| 결제수단 |

|

|---|---|

| 취소 |

|

| 반품 |

|

| 환급 |

|

교환 및 반품 접수

| 교환 및 반품 접수 기한 |

|

|---|---|

| 교환 및 반품 접수가 가능한 경우 |

|

| 교환 및 반품 접수가 불가능한 경우 |

|

교환 및 반품 신청

| 교환 절차 |

|

|---|---|

| 반품 절차 |

|